Powder Materials for Special Usage

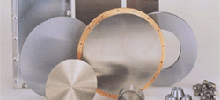

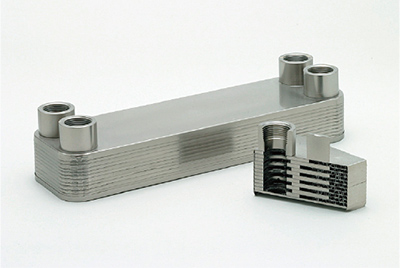

High-purity alloy powder can be applied to sputtering targets after densification by HIP. It is also effective for improving corrosion resistance by thermal spraying, overlaying and brazing.

Features

- Metal is molten under the semi-floating state inside a water-cooled cooper crusible,and atomized with argon gas.

- Possible to manufacture high-purity metal powder with low level of impurities, by preventing oxgen and other contaminants from the crucible.

Main applications

- High purity target materials

- Aerocraft parts

- Braizing filler

- Titanium cutting tools

- Marine plants and chemical plants

- Medical equipment parts

- Sports gear

Main powder products

| Material | Particle size(µm) |

| Ti-6Al-4V | -250 |

| Ti-15Mo | -250 |

| Ti-36Al | -250 |

| Ni-base super alloy | -250 |

High Speed Steel and Other Type of Tool Steel Powder

Features

- Gas atomization method enables to produce spherical metal powder with high filling density and less oxygen content.

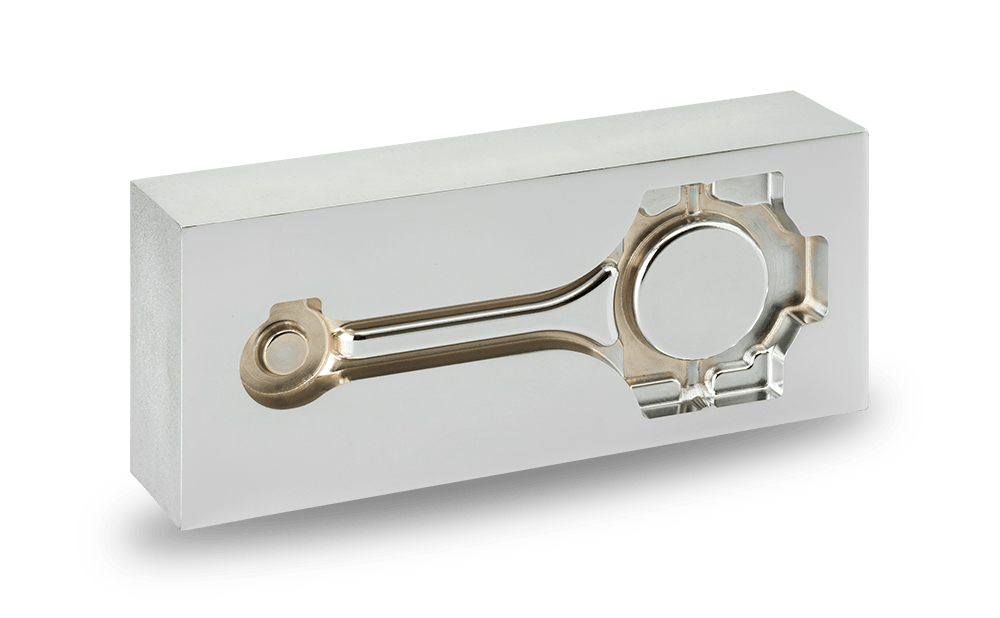

- Possible to manufacture products with homogeneous microstructures from materials that have been difficult to hot-work and the materials that have been difficult to process with a smelting method,through the combination with hot isostatic pressing (HIP)

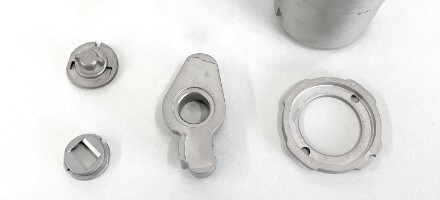

Main applications

- Various rolls (Hot rolling and Cold rolling)

- Various tools (End Mill, Pinion Cutter, Broach Drill, Cutting tolls)

- Die materials, Die parts, Sintered Parts

Main powder products

| Material | Chemical Composition(mass%) | Powder properties |

Characteristics and correspomding steel type |

||||||

| C | Cr | Mo | W | V | Co | A0(g/cm2) | FR(S/50g) | ||

| DAP520 | 1.30 | 4.0 | 5.0 | 6.5 | 3.0 | - | 5 | 12 | DEX20 HRC≧63 |

| DAP540 | 1.30 | 4.0 | 5.0 | 6.5 | 3.0 | 8.0 | 5 | 12 | DEX40 HRC≧63 |

| DAP560 | 1.70 | 4.0 | 2.0 | 15.0 | 5.0 | 8.0 | 5 | 12 | DEX60 HRC≧66 |

| DAP580 | 2.10 | 4.0 | 6.0 | 14.0 | 5.5 | 12.0 | 5 | 12 | DEX80 HRC≧67 |

| DAPSKH51 | 0.85 | 4.2 | 5.0 | 6.0 | 2.0 | - | - | - | SKH51 HRC≧63(M2) |

| DAPSKD61 | 0.38 | 5.0 | 1.2 | - | 1.0 | - | - | - | SKD61 HRC≧53(H13) |

※We can also produce metal powder of chemical compositions not listed in this table.Please contact us.

※The chemical compositions without "Bal." represente iron-based alloys.