Stainless Steel Powder for Sintering

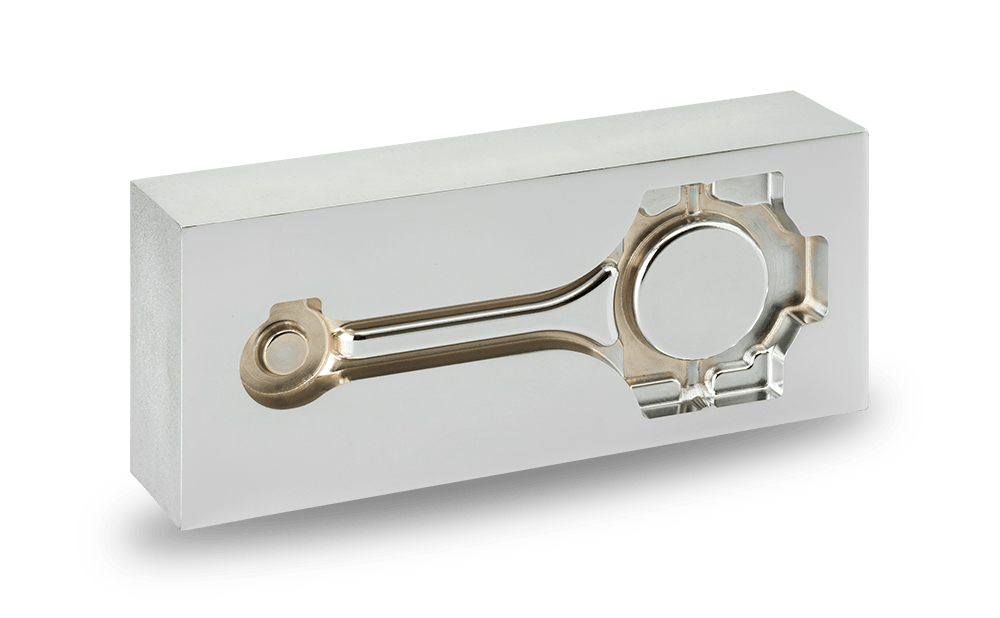

Highly compressible stainless steel powder with corrosion resistance.

Suitable for compacting and sintering process.

Features

- Possible to manufacture various kinds of stainless steel powders.

- Optimal powder shape and particle distribution for compacting and sintering processes.

- Attaining qualitative stabilities by utilizing characteristic control technology.

- Use of low-carbon and low-nitrogen steel billets refined at our steelworks to ensure excellent compressibility without annealing.

- Powders with pre-mixed lubricants are also available.

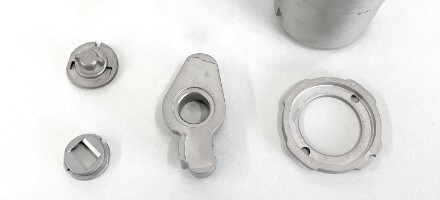

Main applications

- ABS sensor

- Camshaft lobe

- Camera parts

- Lock parts

- Medical equipment parts

- Valve guide

Powder Properties

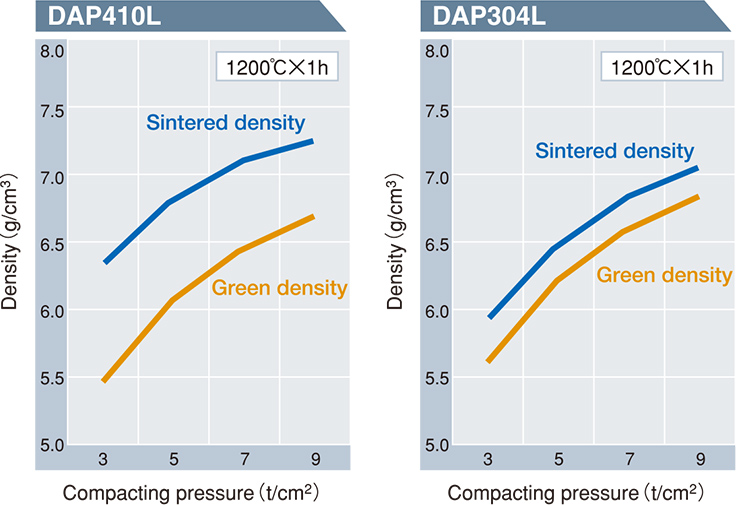

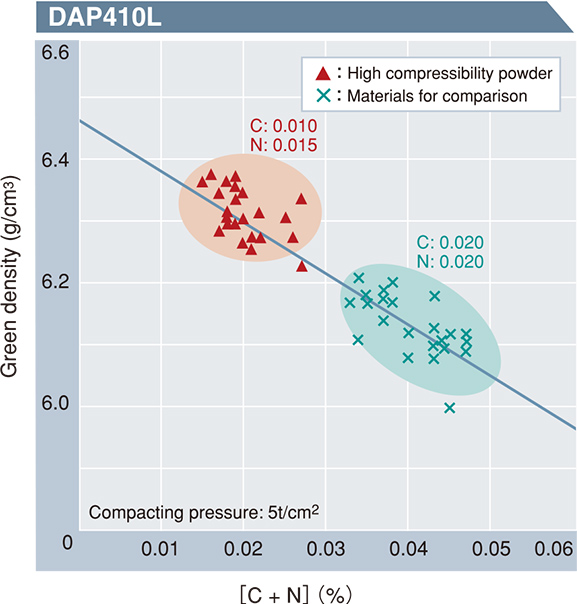

Property of high compressibility powder

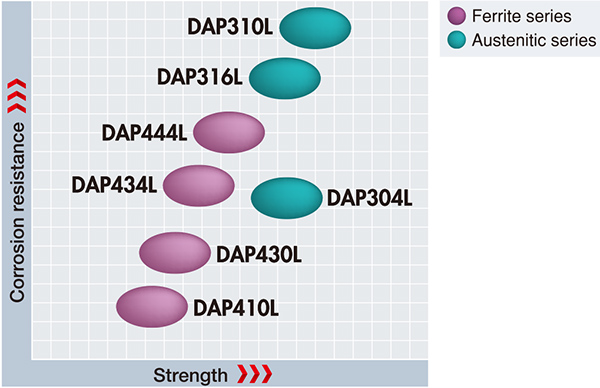

Main powder products

| Material | Chemical Composition (mass%) | Powder Properties | ||||||||

| C | Ni | Cr | Mo | Cu | Sn | AD(g/cm3) | FR(s/50g) | GD(g/cm3) | RV(%) | |

| DAP304L | 0.02 | 11 | 19 | - | - | - | 2.6 | 28 | 6.3 | 2.5 |

| DAP304L-U | 0.02 | 11 | 19 | - | 4 | 0.7 | 2.7 | 25 | 6.4 | 2.5 |

| DAP316L | 0.02 | 13 | 17 | 2.5 | - | - | 2.6 | 27 | 6.4 | 2.0 |

| DAP316LU | 0.02 | 13 | 17 | 2.5 | 2 | 0.7 | 2.7 | 27 | 6.4 | 2.0 |

| DAP310L | - | 21 | 25 | - | - | - | 2.6 | 24 | 6.4 | 2.0 |

| DAP410L | 0.02 | - | 12 | - | - | - | 2.6 | 28 | 6.2 | 2.5 |

| DAP430L | 0.02 | - | 17 | - | - | - | 2.6 | 30 | 6.1 | 2.5 |

| DAP434L | 0.02 | - | 17 | 1.0 | - | - | 2.6 | 28 | 6.0 | 2.5 |

| DAP444L | 0.02 | - | 18 | 2.0 | - | - | 2.6 | 28 | 6.0 | 3.0 |

Compacting pressure :5t/cm2

※We can also produce metal powder of chemical compositions not listed in this table.Please contact us.

※The chemical compositions without "Bal" represent iron-based alloys.

※Highly compressible stainless steel(for each material)