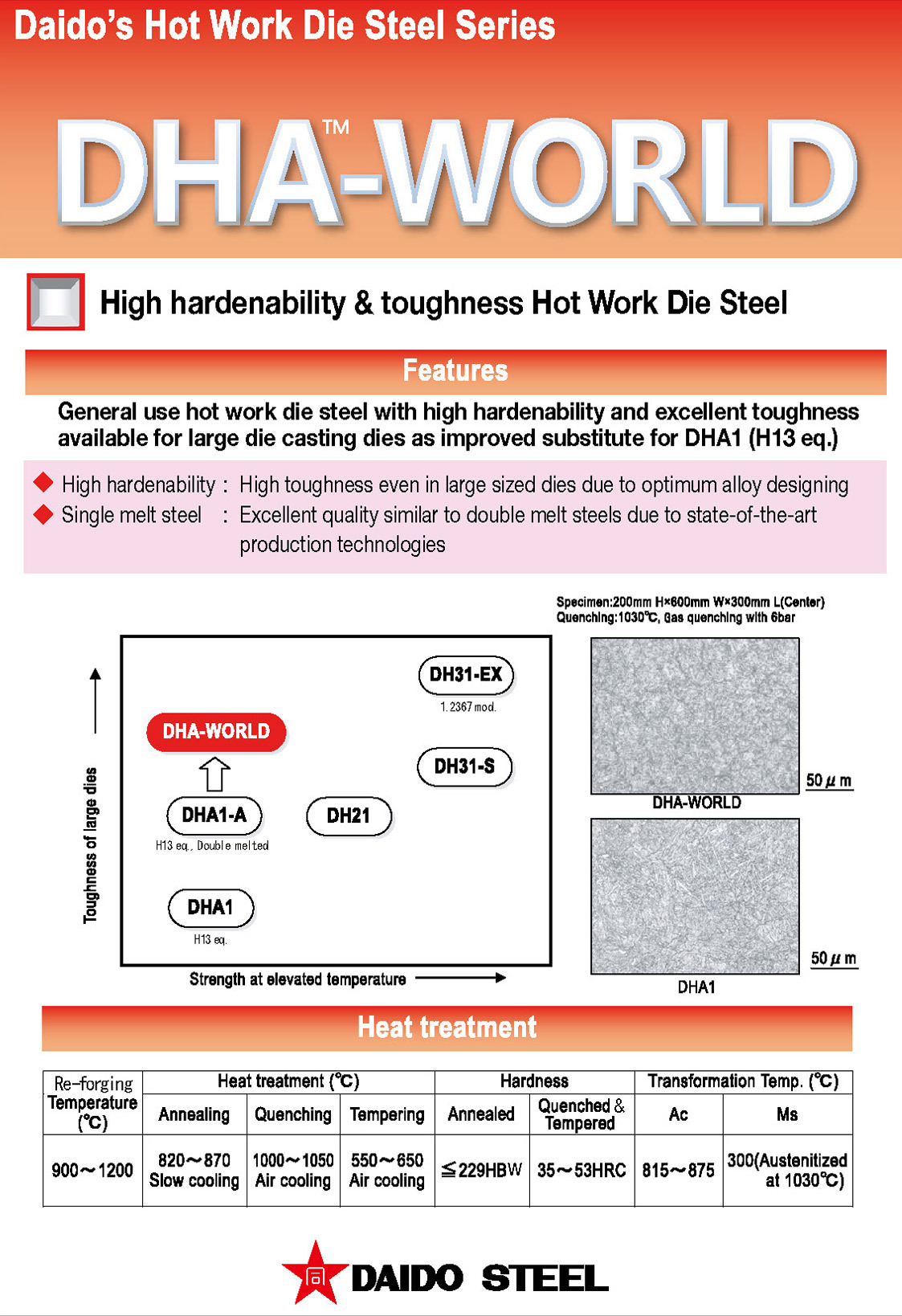

DHA-WORLD

Daido's manufacturing technology is opening new door to next-generation material standard

Daido Steel's high-reliable conventional hot work die steel, DHA-WORLD is suitable material for die cast molds.

It is easily heat-treated and able to gain fine structure to the center as well as high toughness.

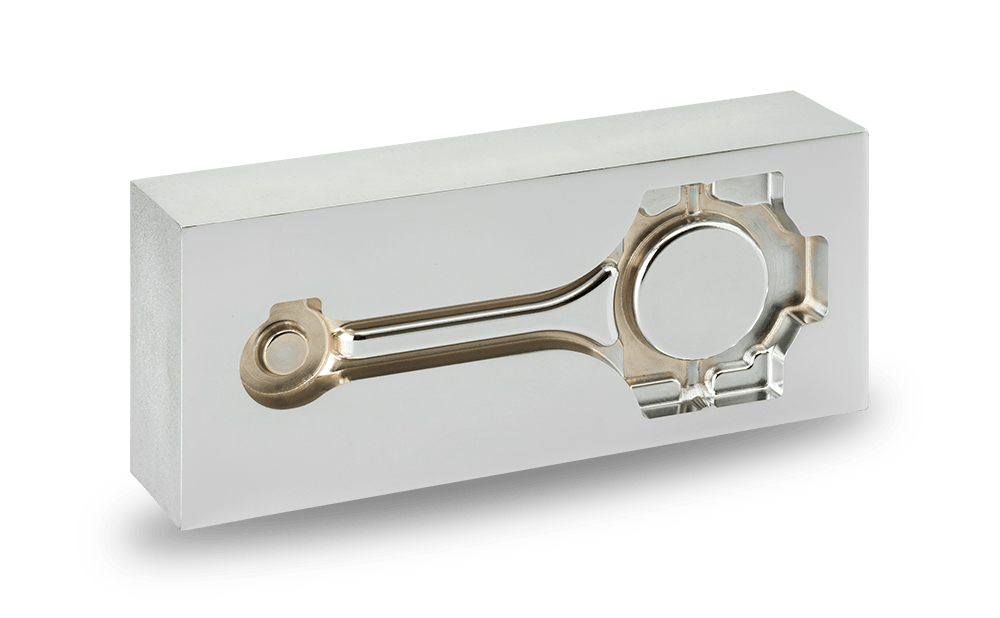

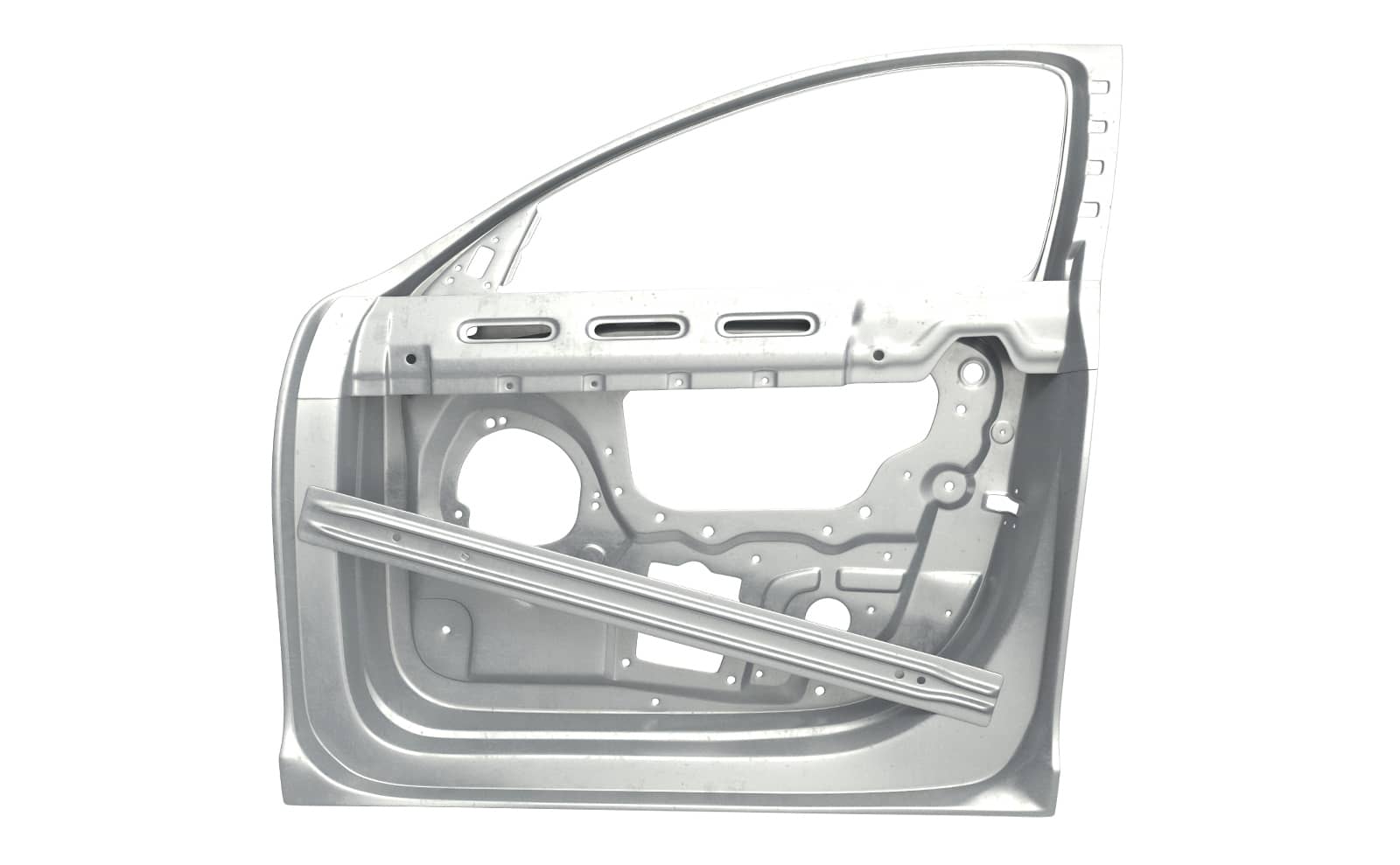

Examples of Applications

Automotive Trasmission Cases

Automotive Cylinder Blocks

Motorcycle Cylinder Blocks

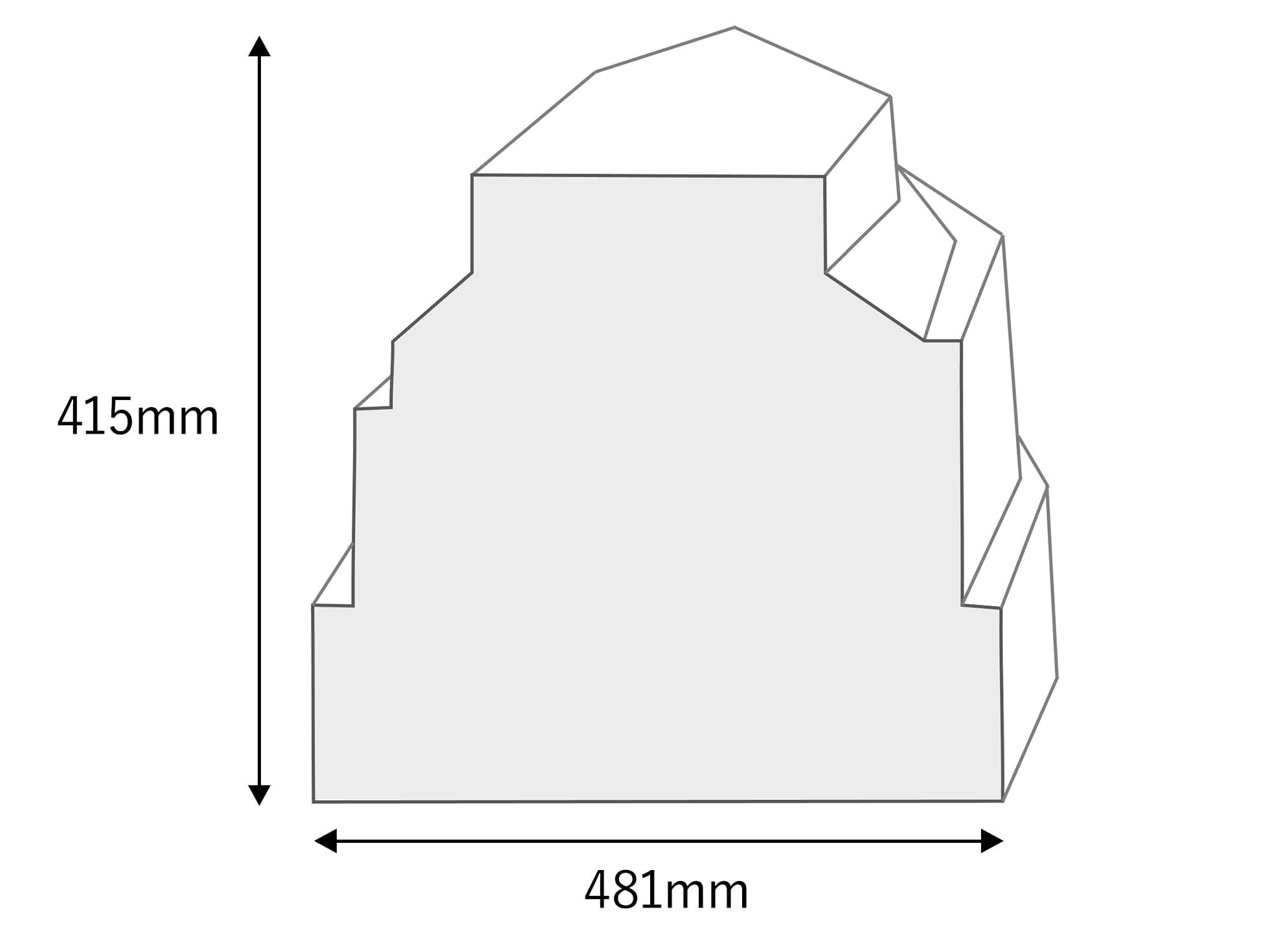

Physical heat treatment test

[1] Test Condition

Evaluating internal quality using the mold simulating center cores of transmission case

- Model mold size: 481×415×526mm (370kg)

- Test method: High performance heat treatment (e-HIT etc.)

- Comparison of DHA-WORLD and JIS SKD61 (AISI H13, DIN 1.2344)

- Internal temperatures were measured

- Hardness: 43HRC

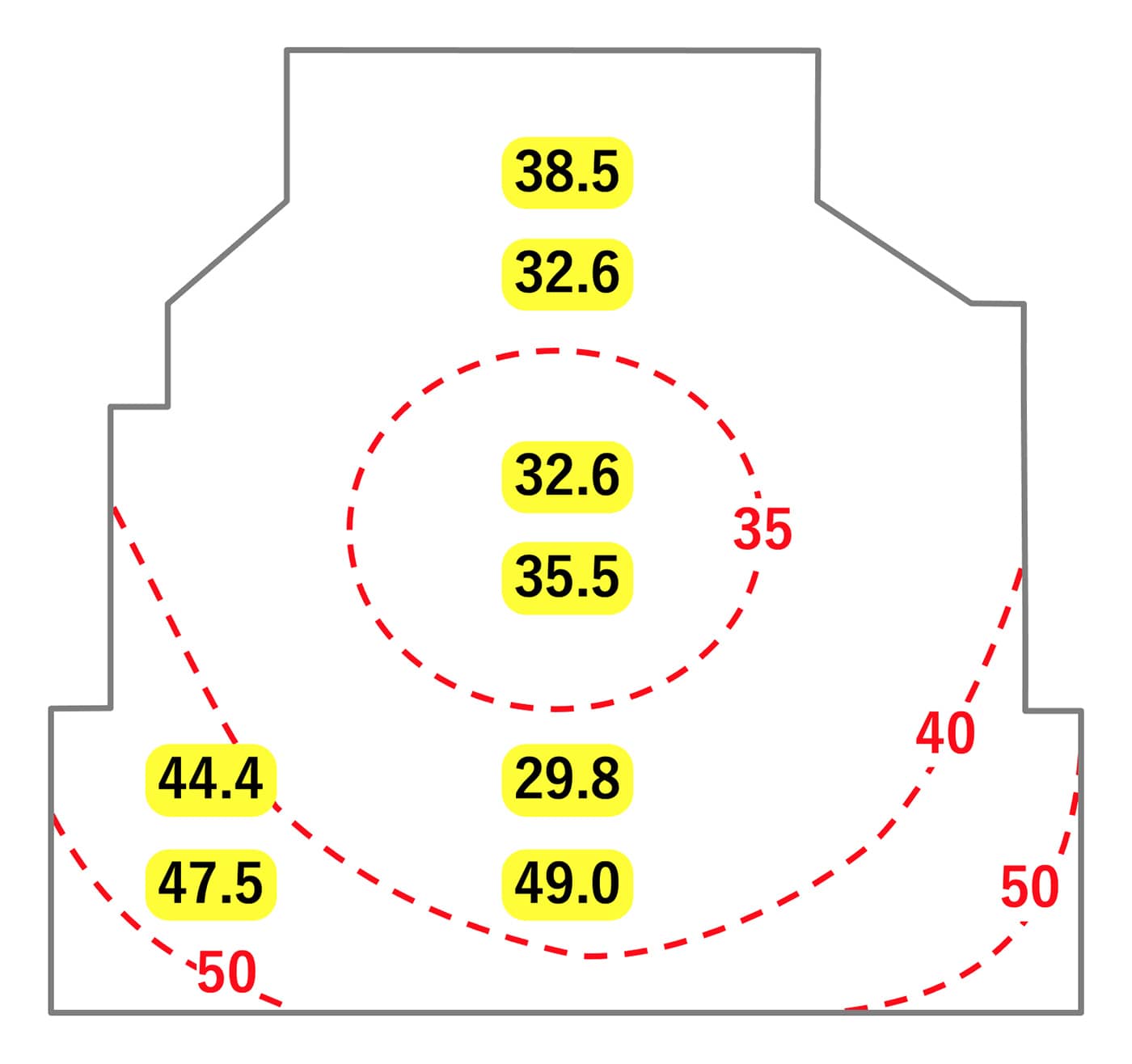

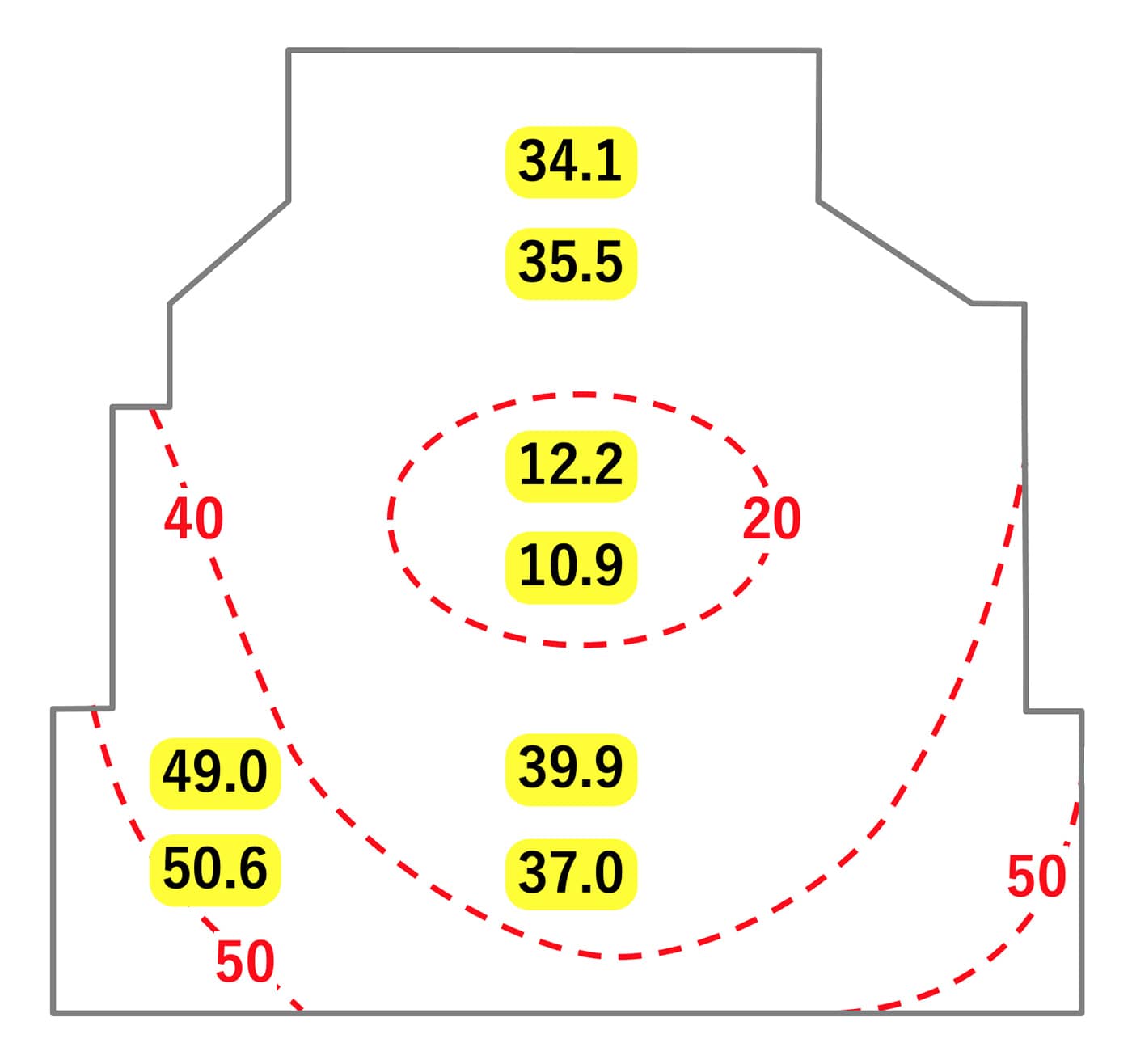

[2] Charpy impact values of mold center

- Cooling rate at the mold center (400 - 200℃): Approx. 3℃/min

- Hardness: 43HRC

- Charpy specimen: 2mmU notched, H direction

- Numbers in black: actual values (Unit: J/cm2)

(AISI H13, DIN 1.2344)

As center impact value drops are rather small, DHA-WORLD secures high toughness

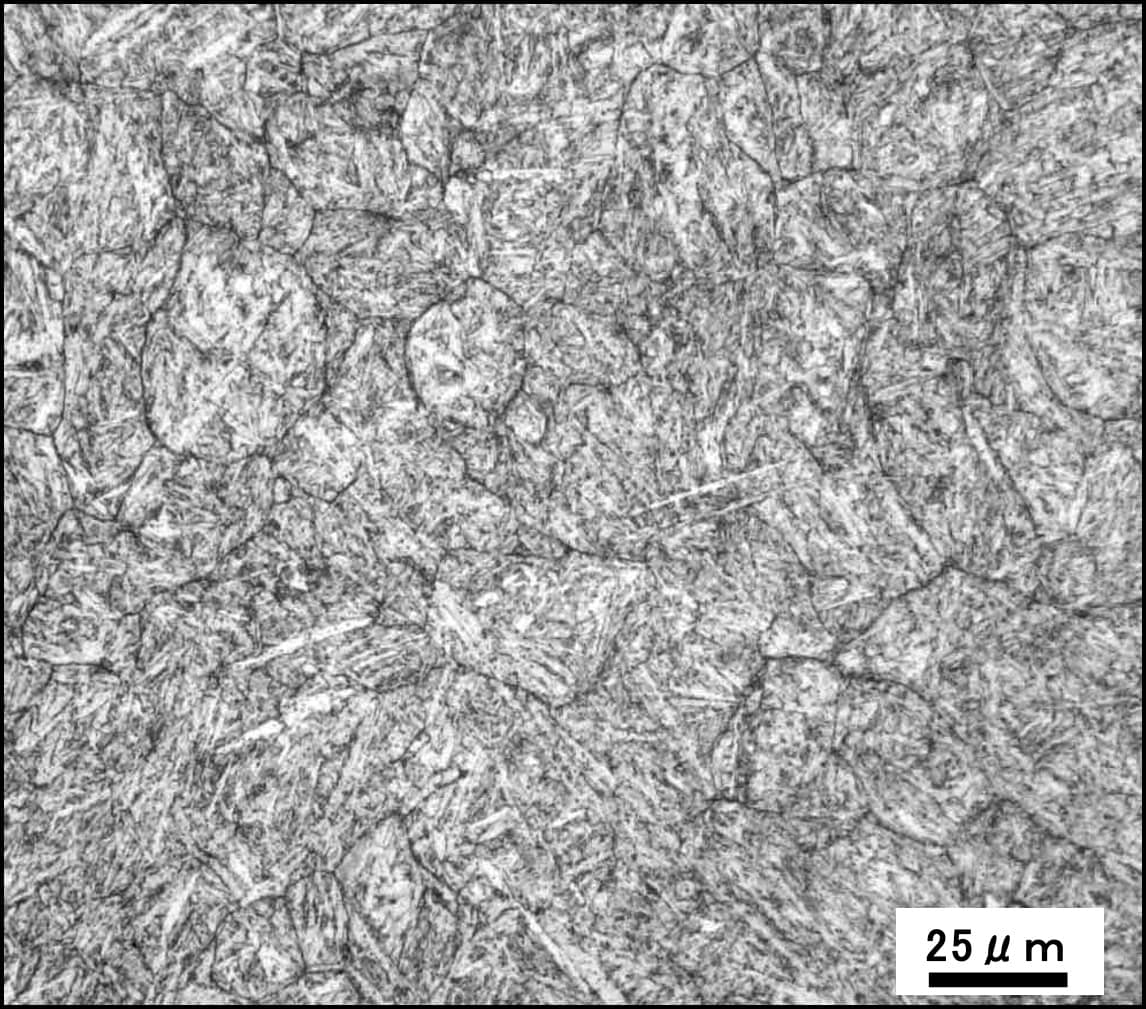

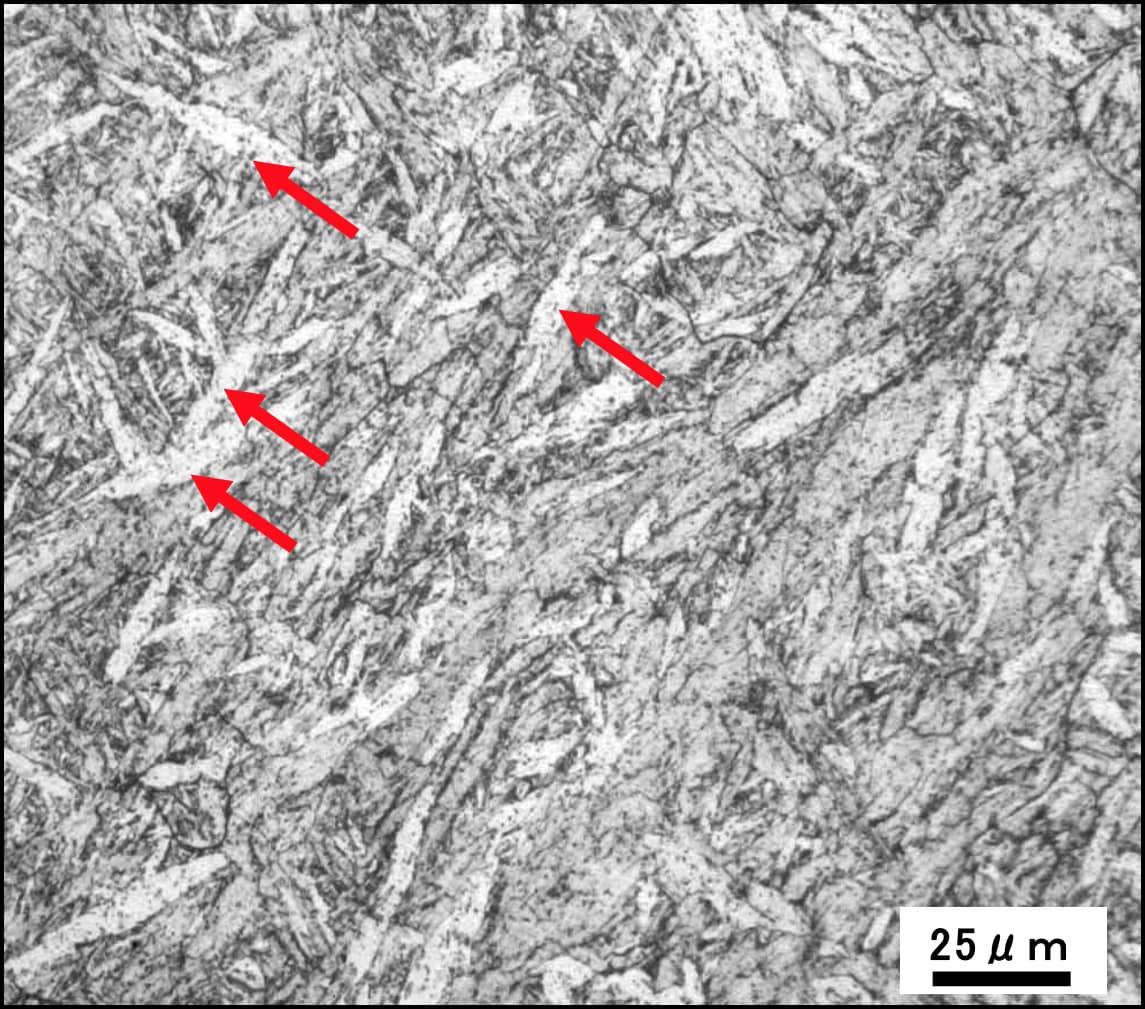

[3] Microstructures of mold center

When the cooling rate during quenching is small, coarse bainitic laths as shown in the picture where the red arrows are pointing tend to generate, which leads to decrease in impact values.

DHA-WORLD has excellent hardenability so even under the cooling rate where those structures generate for SKD61, it secures fine microstructures and high impact toughness.

(AISI H13, DIN 1.2344)

DHA-WORLD has fine microstructures to the mold center because of its excellent hardenability

Brochure

Technical Data

Source: DENKI-SEIKO (Electric Furnace Steel), vol. 71 (2000), No. 2, p. 119 - 129

DHA is a registered trademark or trademark of Daido Steel Co., Ltd.

We will contact you after confirming the contents.