Font Size

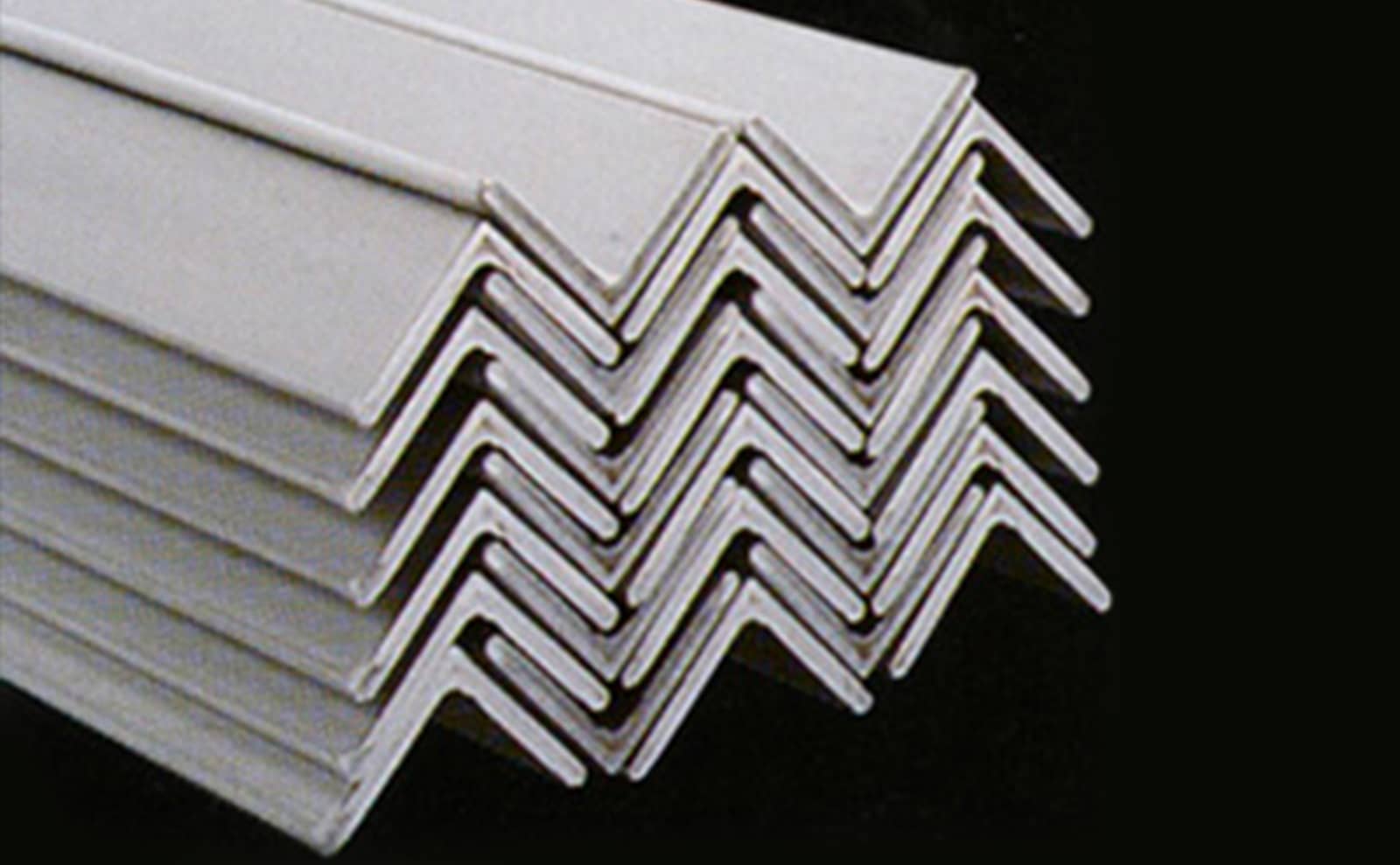

Angle

Features

- Various grades are available other than 304.

- Advanced corrosion resistance and machinability are achieved by optimum control of chemical components and heat treatment.

- Hairline polished products(standard#240) are available. Please ask us about other surface-treated products

- Available of inch-size and inequilateral angle products.

Applications

Chemical machinery, medical apparatus, nuclear application, environmental machinery, industrial machinery, kitchen instrument, architectural material and etc.

Available Size (by inch)

| Thickness(in) | |||||||

| 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | ||

|

Width (in) |

3/4 | .603 | .833 | ||||

| 1 | .813 | 1.16 | 1.49 | ||||

| 1 1/4 | 1.03 | 1.49 | 1.92 | ||||

| 1 1/2 | 1.25 | 1.81 | 2.35 | 2.83 | |||

| 2 | 1.71 | 2.49 | 3.23 | 3.93 | 4.64 | ||

| 2 1/2 | 3.16 | 4.13 | 5.04 | 5.97 | |||

| 3 | 4.99 | 6.11 | 7.26 | 9.41 | |||

| 4 | 6.79 | 8.27 | 9.88 | 13.0 | |||

- Numbers in below table show lbs/ft of SUS304.

Dimensional tolerance Tolerances of thickness and side of equal side angle (mm)

| Thickness(mm) | ||||||||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |||

|

Width (mm) |

20 | ±1.0 | ±0.4 | ±0.4 | ||||||

| 25 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ||||||

| 30 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | ||||||

| 35 | ±0.6 | ±0.6 | ±0.6 | ±0.6 | ||||||

| 40 | ±0.6 | ±0.6 | ±0.6 | ±0.6 | ±0.6 | |||||

| 45 | ±2.0 | ±0.6 | ±0.6 | ±0.6 | ±0.6 | ±0.6 | ||||

| 50 | ±0.6 | ±0.6 | ±0.6 | ±0.6 | ±0.6 | ±0.6 | ±0.6 | |||

| 60 | ±3.0 | ±0.6 | ±0.6 | ±0.7 | ±0.7 | ±0.7 | ||||

| 65 | ±0.6 | ±0.6 | ±0.7 | ±0.7 | ±0.7 | |||||

| 70 | ±0.6 | ±0.7 | ±0.7 | |||||||

| 75 | ±0.6 | ±0.7 | ±0.7 | ±0.7 | ||||||

| 80 | ±0.6 | ±0.7 | ±0.7 | ±0.7 | ||||||

| 90 | ±0.6 | ±0.7 | ±0.7 | ±0.7 | ±0.7 | |||||

| 100 | ±0.6 | ±0.7 | ±0.7 | ±0.7 | ±0.7 | |||||

Squareness : 90°±2°

Warpage : ≦3mm/1m length.

Length : +40,-0mm

Sectional form and sectional characteristics

| Standard section Size (mm) | Sectional area (cm2) | Position of center of gravity (cm) | Sectional secondary moment (cm4) | Sectional secondary diameter (cm) | Sectional coefificient (cm3) | |||||||

| A×B | t | r1 | r2 | a | Cx=Cy | Ix=Iy | MaxIu | MinIv | ix=iy | Maxiu | Miniv | Zx=Zy |

| 20×20 | 3 | 4 | 2 | 1.127 | 0.60 | 0.39 | 0.61 | 0.16 | 0.59 | 0.74 | 0.38 | 0.28 |

| 25×25 | 3 | 4 | 2 | 1.427 | 0.72 | 0.80 | 1.26 | 0.33 | 0.75 | 0.94 | 0.48 | 0.45 |

| 30×30 | 3 | 4 | 2 | 1.727 | 0.84 | 1.42 | 2.26 | 0.59 | 0.91 | 1.14 | 0.58 | 0.66 |

| 30×30 | 4 | 4 | 3 | 2.236 | 0.88 | 1.77 | 2.81 | 0.74 | 0.89 | 1.12 | 0.57 | 0.84 |

| 30×30 | 5 | 4 | 3 | 2.746 | 0.92 | 2.14 | 3.37 | 0.91 | 0.88 | 1.11 | 0.57 | 1.03 |

| 30×30 | 6 | 4 | 4 | 3.206 | 0.94 | 2.41 | 3.79 | 1.04 | 0.87 | 1.09 | 0.57 | 1.17 |

| 40×40 | 3 | 4.5 | 2 | 2.336 | 1.09 | 3.53 | 5.60 | 1.46 | 1.23 | 1.55 | 0.79 | 1.21 |

| 40×40 | 4 | 4.5 | 3 | 3.045 | 1.12 | 4.46 | 7.09 | 1.84 | 1.21 | 1.53 | 0.78 | 1.55 |

| 40×40 | 5 | 4.5 | 3 | 3.755 | 1.17 | 5.42 | 8.59 | 2.25 | 1.20 | 1.51 | 0.77 | 1.91 |

| 40×40 | 6 | 4.5 | 4 | 4.415 | 1.20 | 6.19 | 9.79 | 2.58 | 1.18 | 1.49 | 0.76 | 2.21 |

| 50×50 | 4 | 6.5 | 3 | 3.892 | 1.37 | 9.06 | 14.4 | 3.76 | 1.53 | 1.92 | 0.98 | 2.49 |

| 50×50 | 5 | 6.5 | 3 | 4.802 | 1.41 | 11.1 | 17.5 | 4.58 | 1.52 | 1.91 | 0.98 | 3.08 |

| 50×50 | 6 | 6.5 | 4.5 | 5.644 | 1.44 | 12.6 | 20.0 | 5.20 | 1.50 | 1.88 | 0.96 | 3.55 |

| 60×60 | 6 | 6.5 | 4 | 6.862 | 1.69 | 22.8 | 36.1 | 9.40 | 1.82 | 2.29 | 1.17 | 5.29 |

| 65×65 | 6 | 8.5 | 4 | 7.527 | 1.81 | 29.4 | 46.6 | 12.2 | 1.98 | 2.49 | 1.27 | 6.26 |

| 65×65 | 8 | 8.5 | 6 | 9.761 | 1.88 | 36.8 | 58.3 | 15.3 | 1.94 | 2.44 | 1.25 | 7.96 |

| 70×70 | 7 | 8.5 | 5 | 9.358 | 1.97 | 41.5 | 65.7 | 17.3 | 2.11 | 2.65 | 1.36 | 8.25 |

| 75×75 | 6 | 8.5 | 4 | 8.727 | 2.06 | 46.1 | 73.2 | 19.0 | 2.30 | 2.90 | 1.48 | 8.47 |

| 75×75 | 9 | 8.5 | 6 | 12.69 | 2.17 | 64.4 | 102 | 26.7 | 2.25 | 2.84 | 1.45 | 12.1 |

| 80×80 | 8 | 8.5 | 6 | 12.16 | 2.25 | 71.2 | 113 | 29.3 | 2.42 | 3.05 | 1.55 | 12.4 |

| 90×90 | 9 | 10 | 6 | 15.45 | 2.54 | 114 | 183 | 44.4 | 2.72 | 3.44 | 1.70 | 17.6 |

| 100×100 | 8 | 10 | 6 | 15.42 | 2.75 | 145 | 230 | 59.3 | 3.07 | 3.86 | 1.96 | 20.0 |

| 100×100 | 10 | 10 | 7 | 19.00 | 2.82 | 175 | 278 | 72.0 | 3.04 | 3.83 | 1.95 | 24.4 |

Inquiries about Stainless Steel

Search Stainless Steel

Application

(Ex. Free-cutting, Cold Deformation)

Classification

(Ex. Austenitic)

Characteristics Map

(Ex. Strength & Corrosion Resistance)

Shape

(Ex. Flat Bar, Channel, Angle)