Font Size

Vacuum and sintering furnaces

Products list

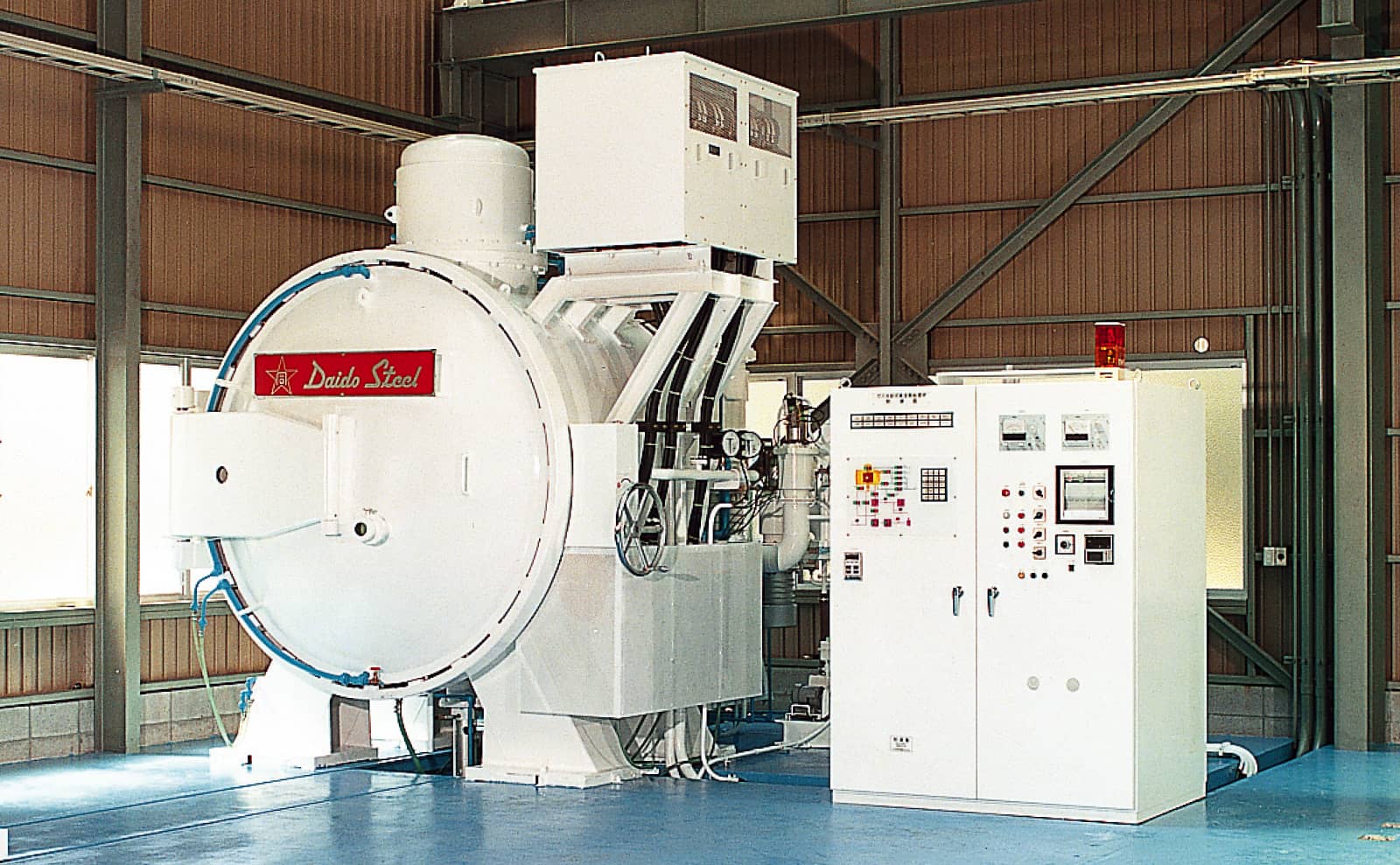

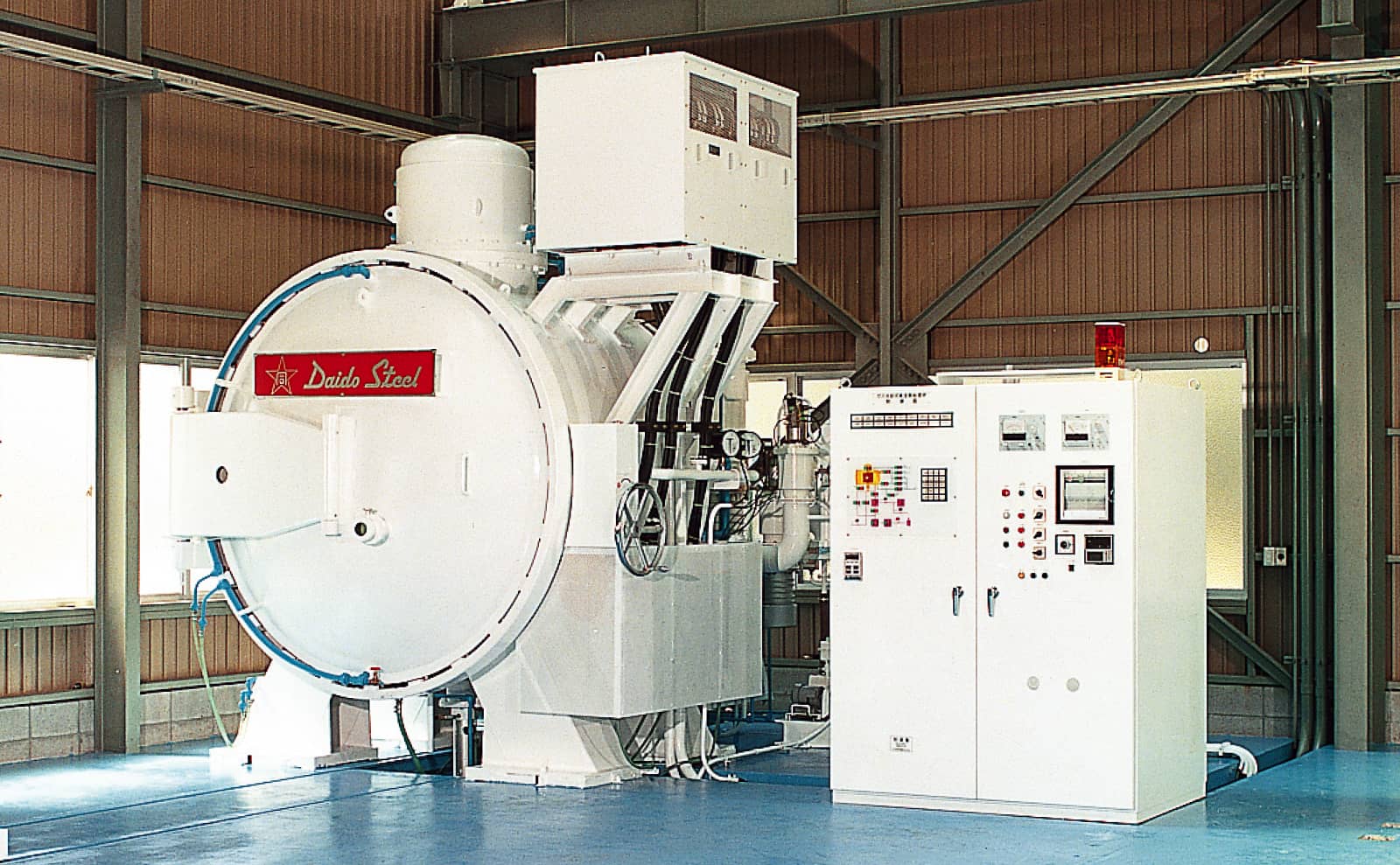

Vacuum heat treatment furnace

- An automatic high quality vacuum furnace. Used for quenching, tempering, annealing and other heat treatment of metals. Rapid and homogeneous cooling for furnace efficiency and easy maintenance.

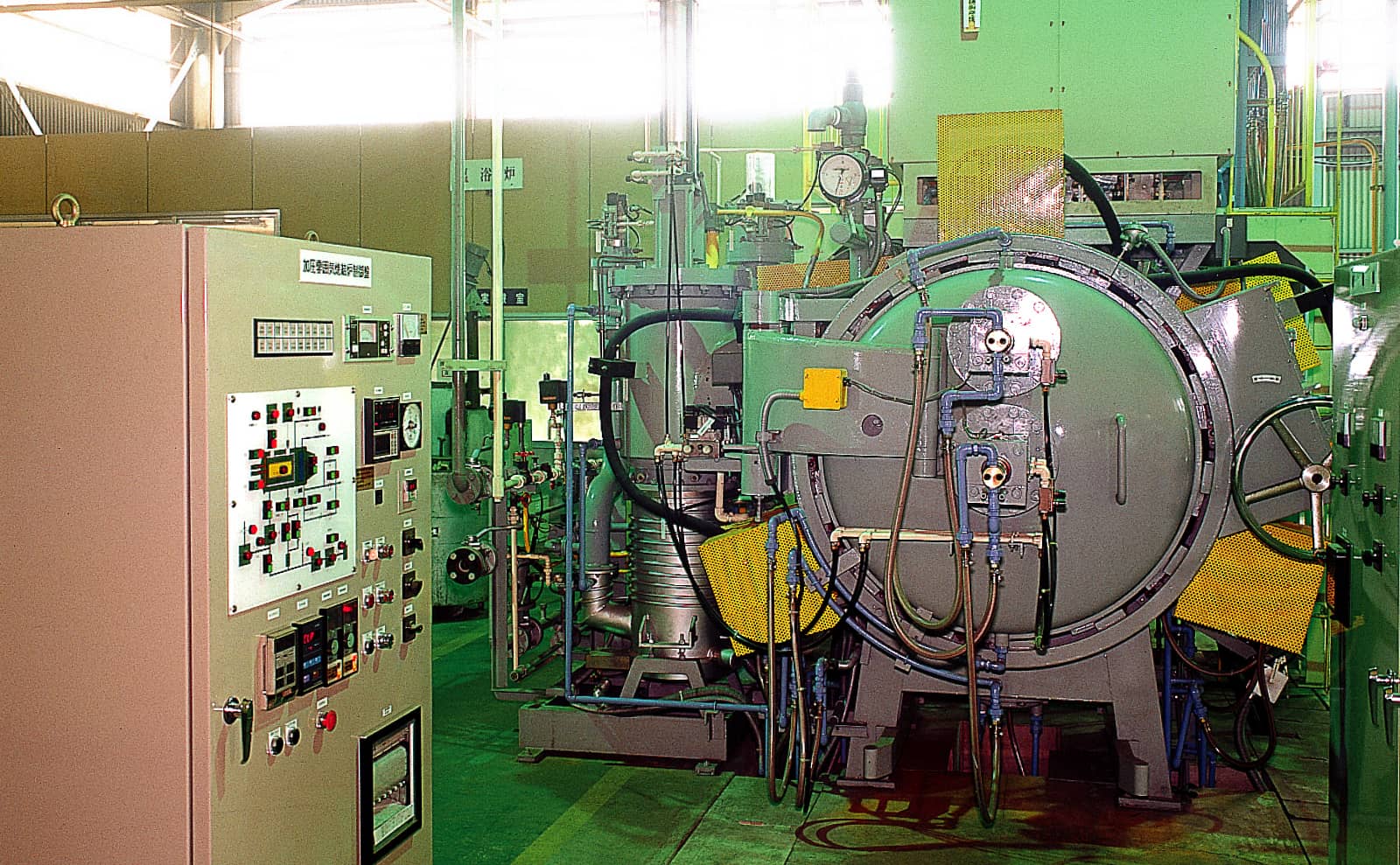

Sintering furnace

- Single chamber furnace

-

Removes binder, sinters, and cools in one chamber. Renowned for its excellent operability.

- Double chamber furnace

-

- Has two separate chambers for binder removal / sintering and cooling.

- Provides a cleaner atmosphere for sintering since the sintering chamber is segregated from outside air.

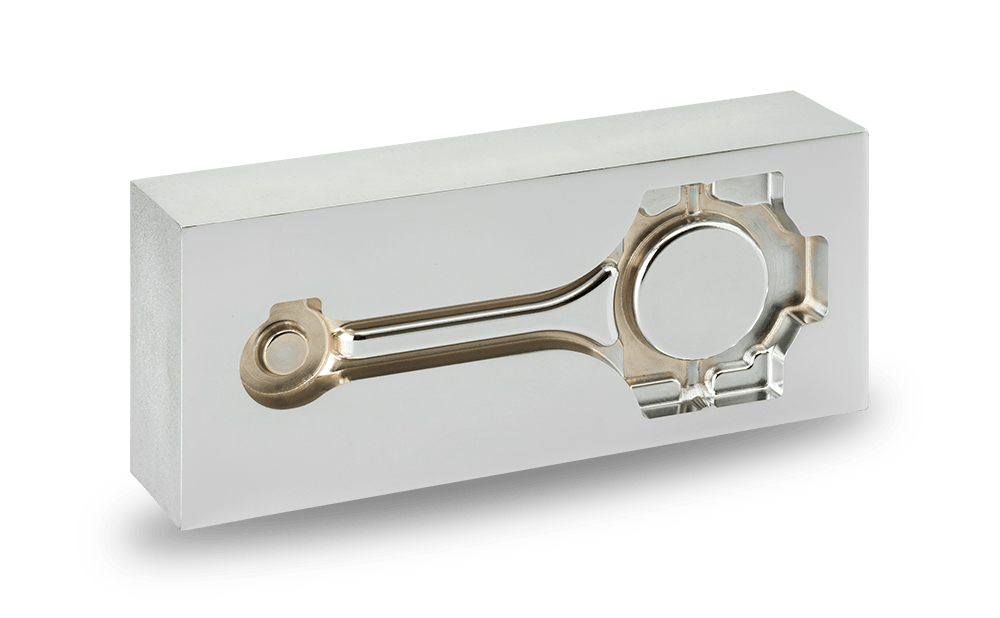

Metal injection molding furnace

- A vacuum heat treatment furnace for sintering of powders of alloy steel, stainless steel, and rare-earth for molding etc.

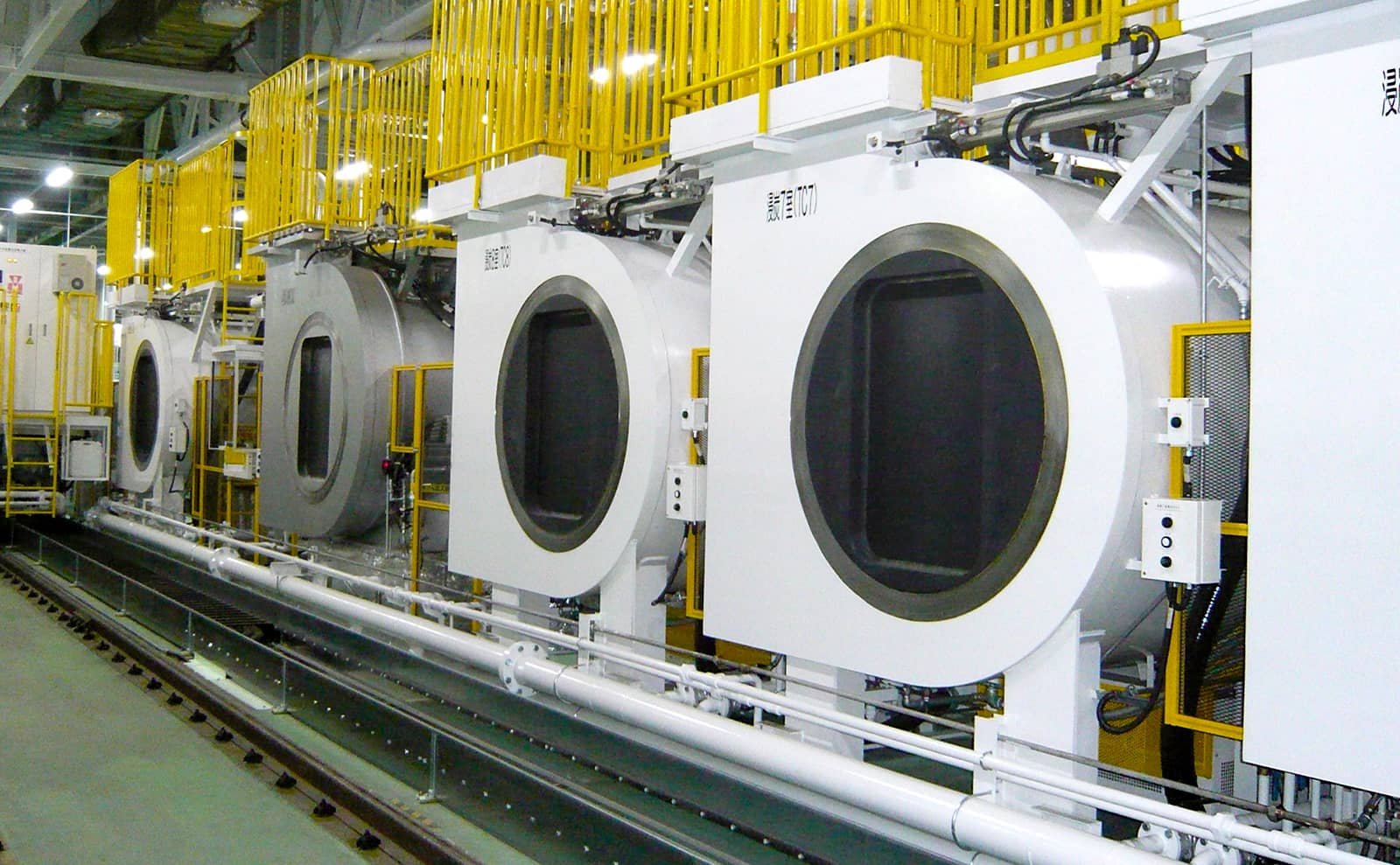

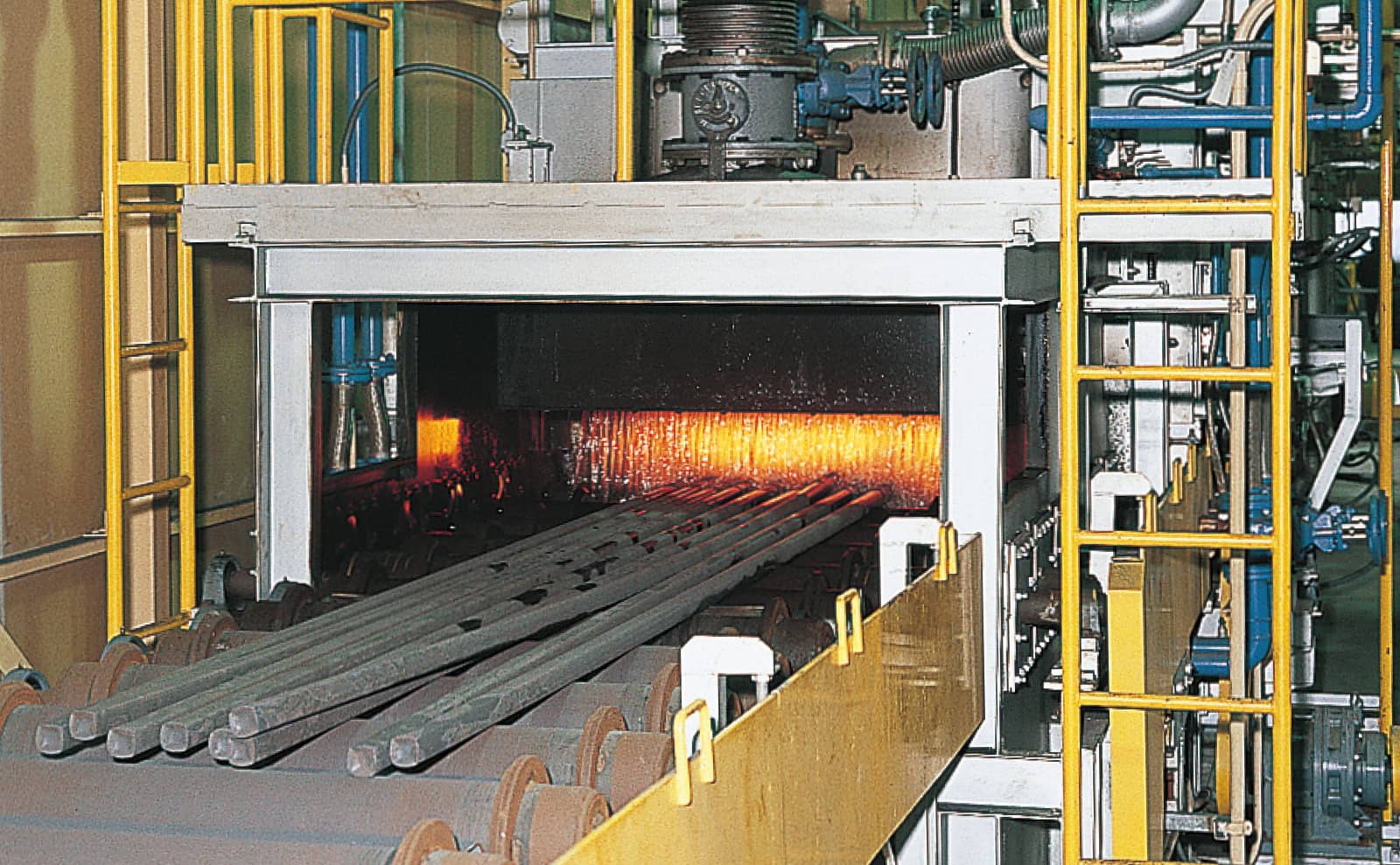

Roller hearth continuous vacuum furnace

- Used for continuous process of removing binder, sintering , and cooling of powder molds and for general heat treatment.

- Achieves short term delivery by combining independent standard function units (e.g. sintering unit, cooling unit), allowing various different compositions.