Daido Steel Co., Ltd. (President: Tetsuya Shimizu) has developed the MED8P76A infrared point source LED*1, which has an ultra-small emitting window diameter of φ35μm and is capable of operating in high-temperature environments of 125℃. Sample orders will begin being accepted from December 2025.

By using this product, it is possible to achieve high resolution and high temperature operation of optical encoders, which are issues when miniaturizing robots, and contribute to the miniaturization of the entire device.

1.background

In recent years, industrial robots such as collaborative robots*2 have become increasingly popular in manufacturing sites due to a labor shortage, and there is a demand for further miniaturization.

When trying to make robots smaller, the diameter of the code wheel of the optical encoder (a position sensor that uses LED light to illuminate a disk-shaped part with slits called a code wheel, and detects the angle and speed of the rotation axis from the transmission pattern) also becomes smaller, and the slit spacing becomes denser, making it difficult to read.

In such a situation, high resolution is required to ensure that the light does not spill over into adjacent slits. To achieve this, an infrared point source LED with a small light spot diameter is effective. Furthermore, in order to make robots smaller, there is a trend to pack the servo motors and optical encoders they are equipped with closer together.

However, this packing causes the internal environmental temperature to rise more than ever before, so there is now a need for drive stability in high-temperature environments for the parts surrounding the motors.

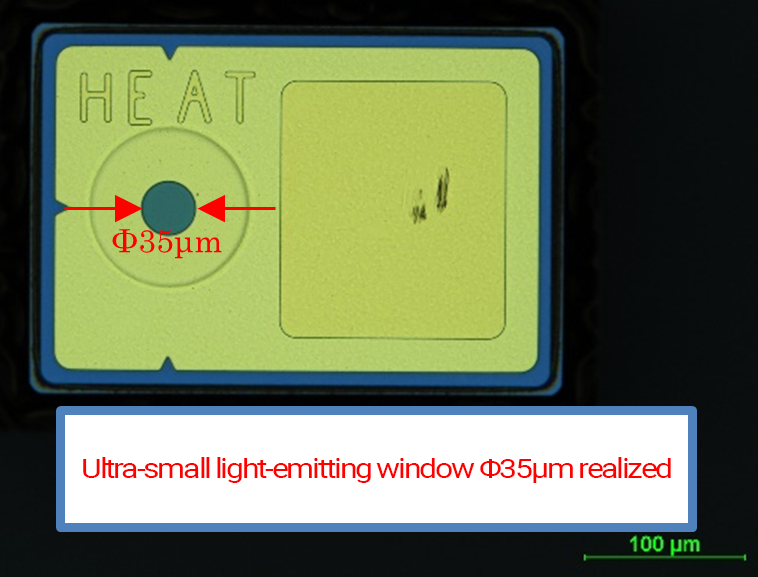

To meet these needs, we have developed the MED8P76A infrared point source LED, which has an ultra-small light-emitting window diameter of φ35μm and can operate in high-temperature environments up to 125℃.

2.Features

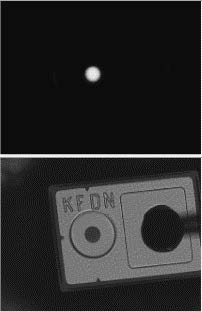

- A small spot diameter of φ35μm is achieved with an ultra-small light emitting window (Fig. 3, 5).

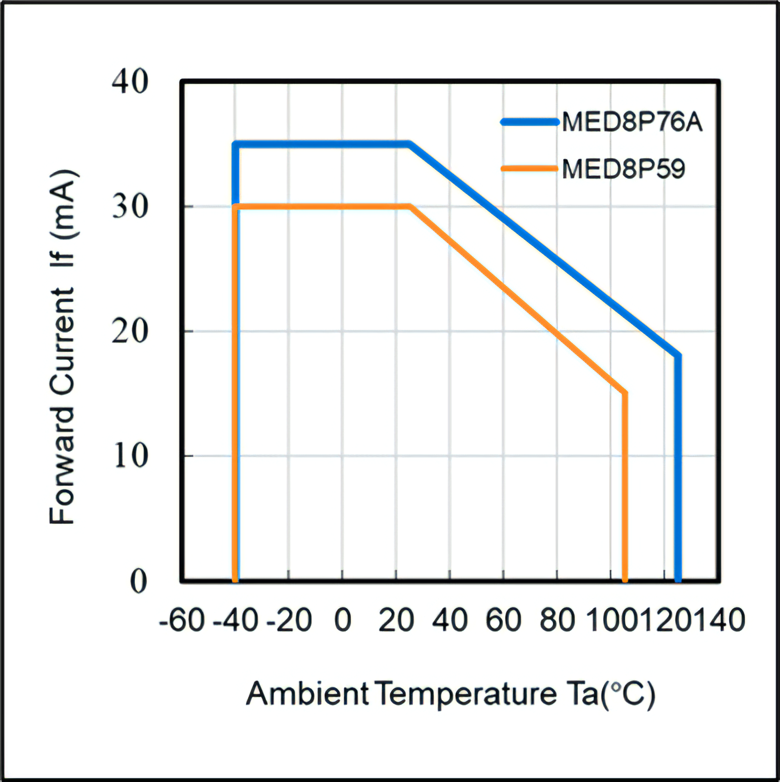

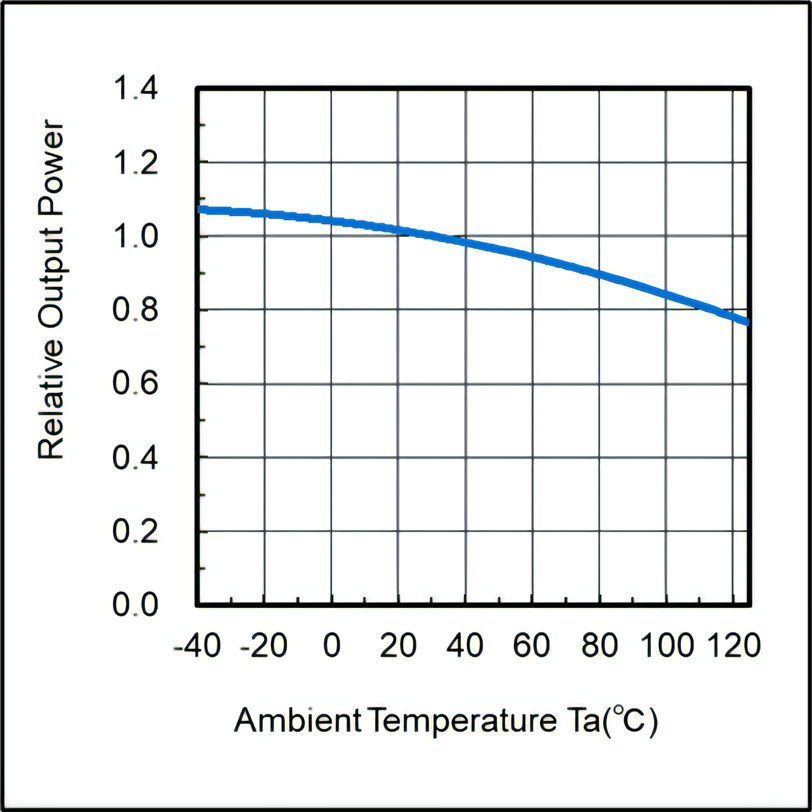

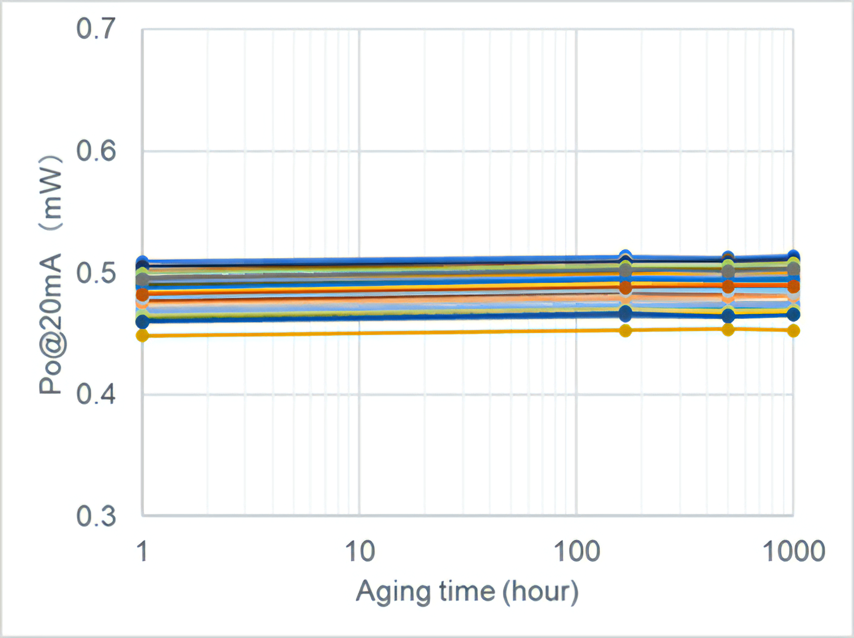

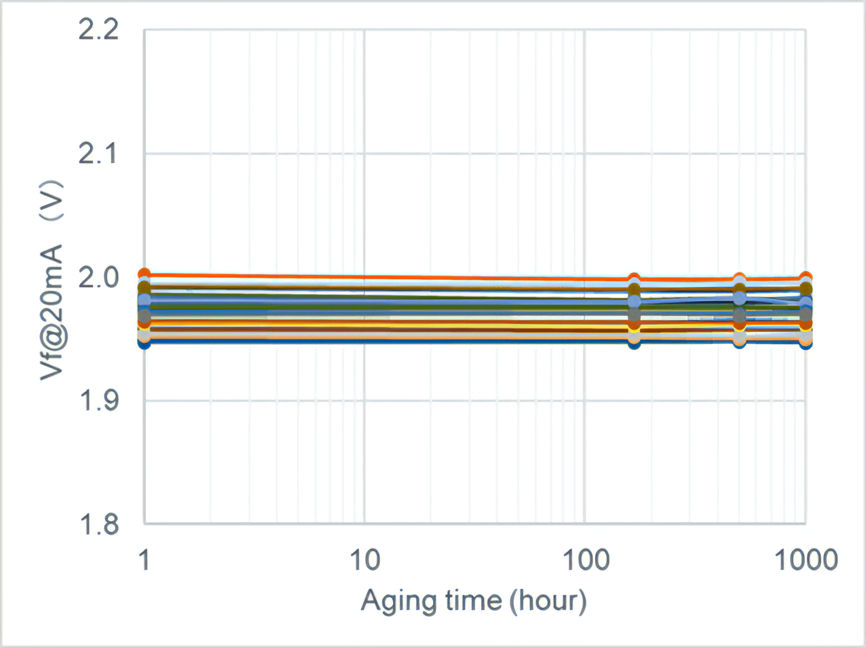

- The design of the structure disperses the localized current concentration around the light-emitting window, reducing the risk of LED light intensity degradation and enabling stable operation even in high-temperature environments of 125°C (Fig. 11 and 12).

※4-digit address engraved on the LED surface enhances traceability within the wafer

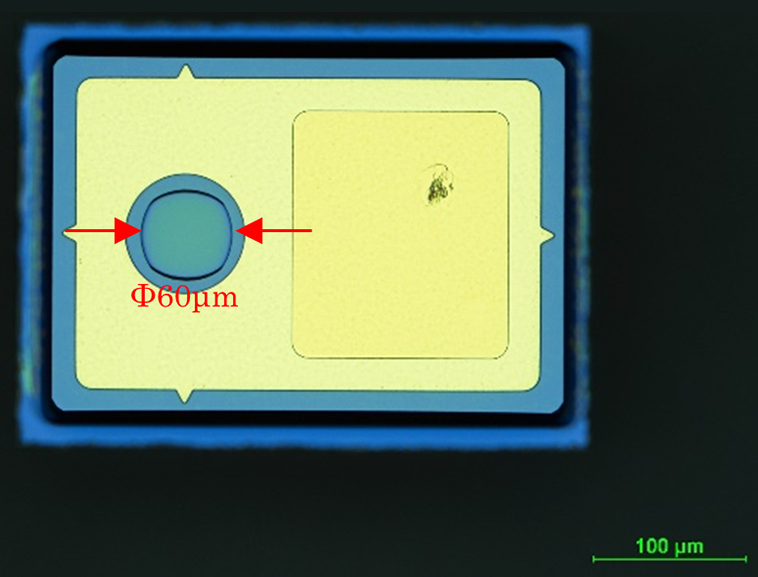

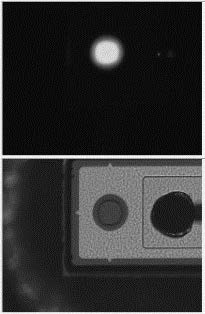

(※Our existing φ60 model)

Compared to existing products, the light-emitting window is smaller but the light edge is sharper

(※Our existing φ60μm model)

(MED8P59 is our existing φ35μm model)

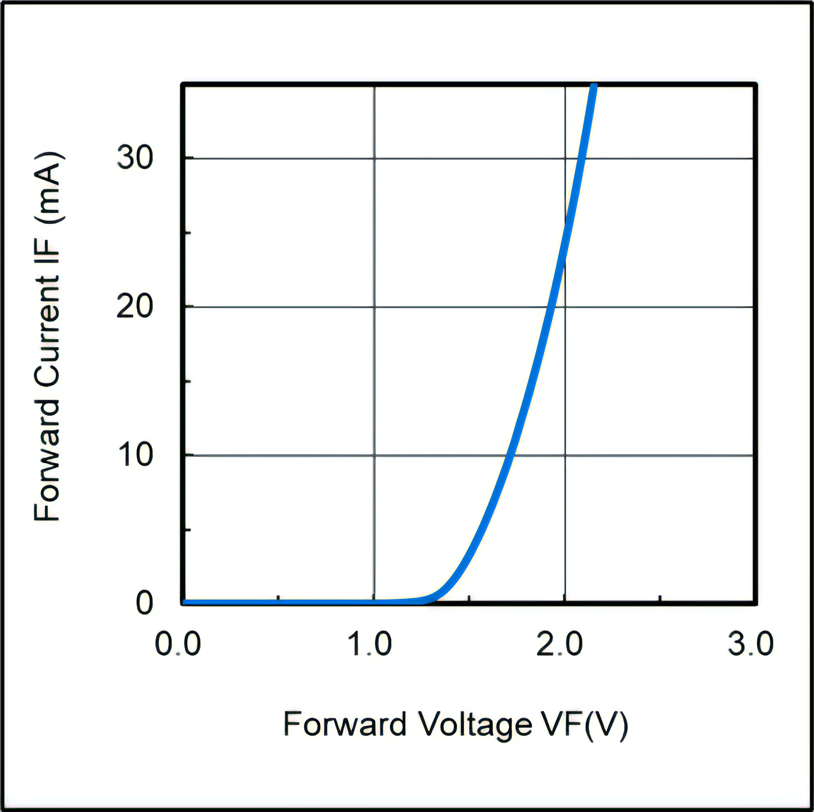

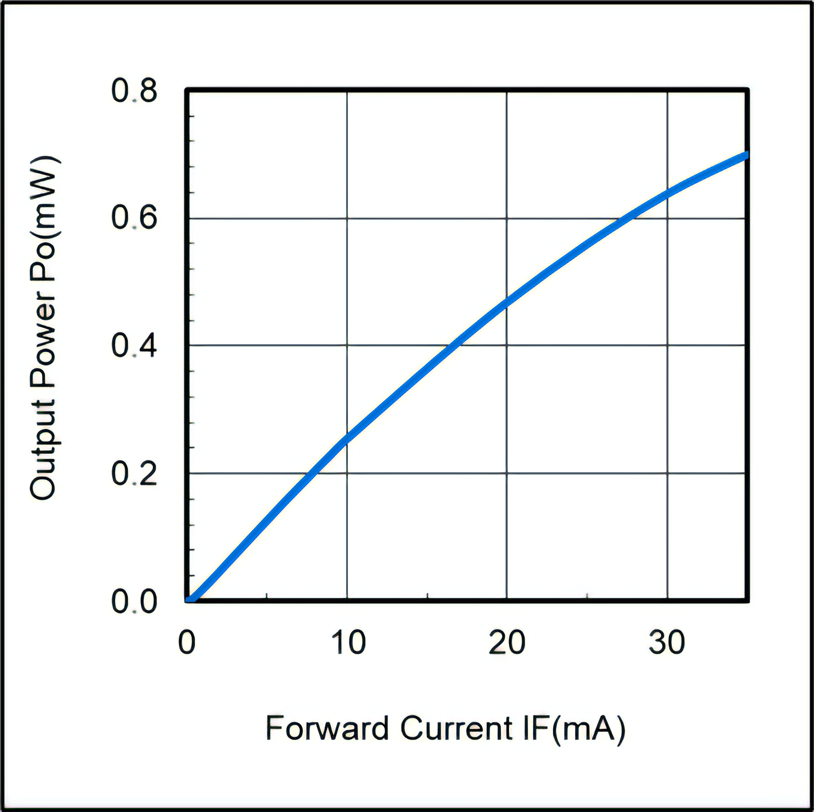

(Maximum rated current: 35mA)

Achieves stable operation for 1000 hours in a 125℃ environment

however, the rated current at 125℃ is 18mA)

however, the rated current at 125℃ is 18mA)

3.Purpose

End applications: industrial robots, collaborative robots, machine tools, semiconductor manufacturing equipment

LED applications: optical encoders for servo motors, photoelectric sensors, etc.

Terminology

| ※1 Point source LED | Unlike surface-emitting LEDs, which emit light from the entire top surface of the LED, point source LEDs have a spot-shaped light-emitting window. Also, surface-emitting LEDs have a bonding pad in the center of the die, which casts a shadow, but point-light-source LEDs have a separation between the light-emitting window and the electrode pad, so no shadow is cast. |

| ※2 Collaborative robot | An industrial robot that can work safely in the same space as humans. While conventional industrial robots operate in areas enclosed by safety fences, collaborative robots are equipped with safety features that detect contact with humans and stop them, allowing them to work cooperatively in the same workspace. This requires more delicate control. |

| ※3 Temperature derating curve | Temperature derating is a measure to prevent damage to internal components due to overheating and to improve the reliability and lifespan of a product by intentionally limiting capacity within a safe operating range. The relationship between temperature and current is usually shown as a derating curve. |

Contacts

Daido Steel Co., Ltd.

Functional Products Business Div.Electronic Materials Dept.

Opt-electronic Devices Sect.

Contact form:https://www.daido.co.jp/en/products/machinery/index.html